Making Process

1. Component Selection

The component selection for our Smart Manufacturing Kit was a collaborative effort

undertaken by the Smart Manufacturing Lab at Birla Vishvakarma Mahavidyalaya (BVM) and the IITD-AIA Foundation

For Smart Manufacturing. This phase was crucial, as we meticulously chose each component to ensure it was

perfectly suited to our specific requirements, laying a solid foundation for the subsequent stages of the

project.

2. Desinging and Manufacturing

Building our Smart Manufacturing Kit was a transformative journey that spanned seven

months, marked by meticulous planning, design, and assembly. Utilizing Autodesk Fusion 360 software, I

meticulously crafted the kit’s design, paying attention to every intricate detail to ensure precision and

functionality.

The real challenge and excitement began during the assembly phase. Hours were dedicated

to fitting each piece in place, ensuring everything aligned perfectly. This hands-on process was both demanding

and rewarding, as it brought the digital design to tangible life.

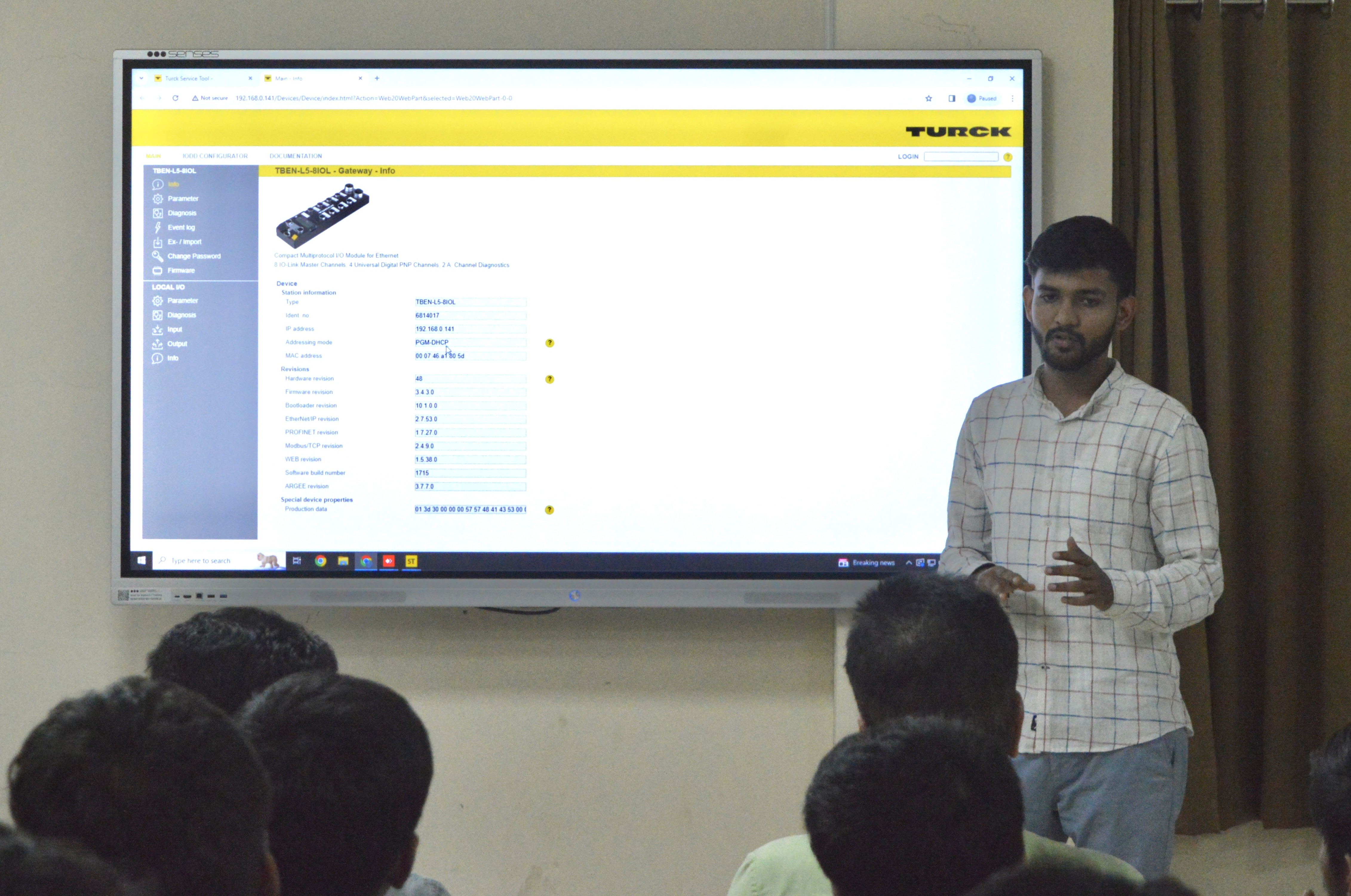

3. Programming and Testing

After completing the assembly and wiring of the kit, the programming and testing phase

began. This stage was challenging, requiring multiple meetings with Turck's official technical team to address

various issues related to connectivity and sensor integration. After several days of intensive work, the

programming and testing were successfully completed, and the kit is now fully functional.