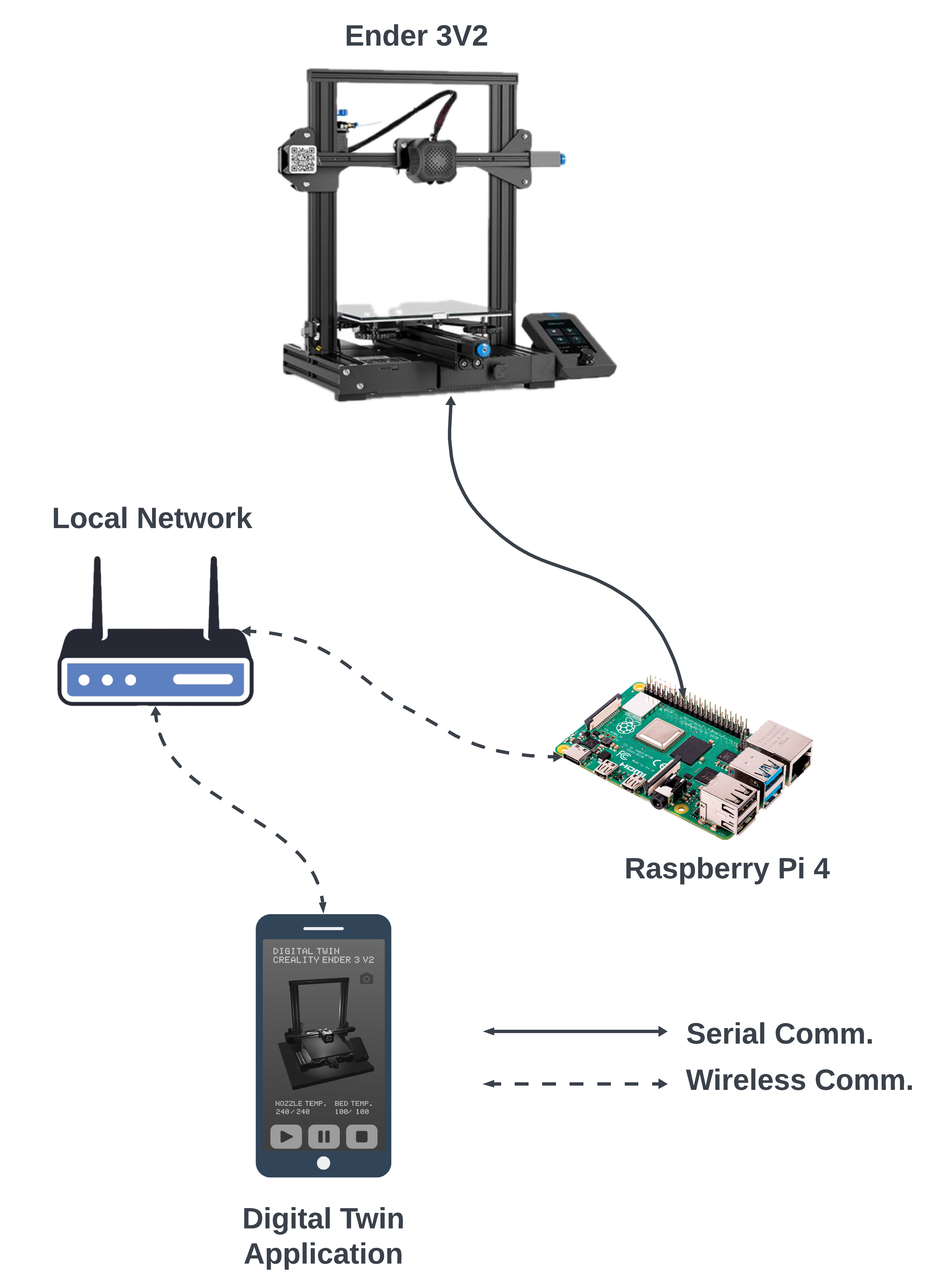

To achieve real-time data acquisition and accurate visualization, a robust methodology was employed. The Flask server was critical for managing the flow of data, while specific G-codes enabled precise tracking of the printer’s movements. Two API endpoints were developed: one for positional data and another for temperature metrics, ensuring that the data transmitted was both accurate and timely.

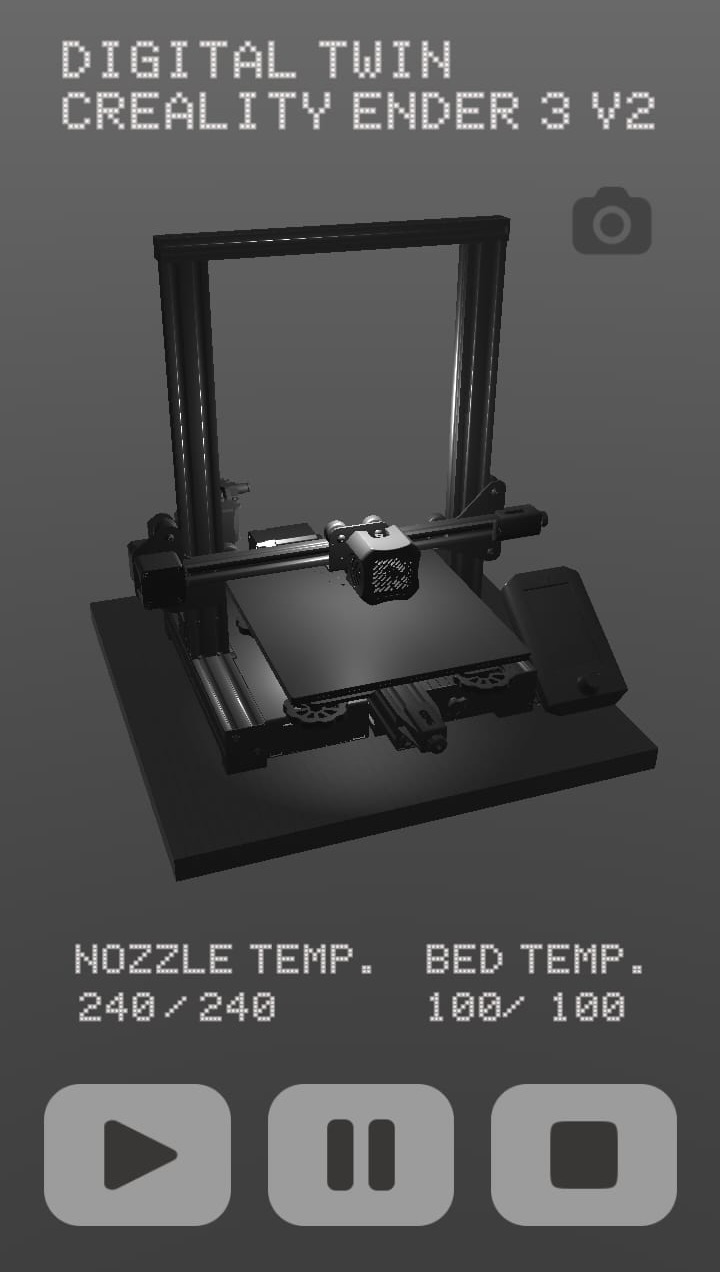

The Unity application served as the interface, translating this data into a comprehensive, real-time 3D model of the printing process. This allowed for interactive monitoring and control, significantly enhancing user interactions and operational efficiency.

In the implementation phase, the Raspberry Pi 4B was configured, and a stable connection with the 3D printer was established. Following this, the Flask server and API endpoints for handling the data were developed. A custom C# script facilitated the integration with Unity, ensuring the virtual model was dynamically updated based on real-time data from the APIs.

The project underwent rigorous testing to ensure accuracy and reliability, resulting in a seamless alignment between the physical and digital realms. The system was able to accurately mirror the printer’s movements and environmental conditions, providing a reliable and interactive tool for real-time monitoring and control of the 3D printing process.

This integration has opened up new possibilities for predictive maintenance and process optimization in 3D printing. Future enhancements could include integrating machine learning algorithms for predictive analysis and extending the system's applicability to other manufacturing processes. The project has thus made a significant contribution to the field of digital twins in additive manufacturing, offering a foundation for future advancements in smart manufacturing technologies.