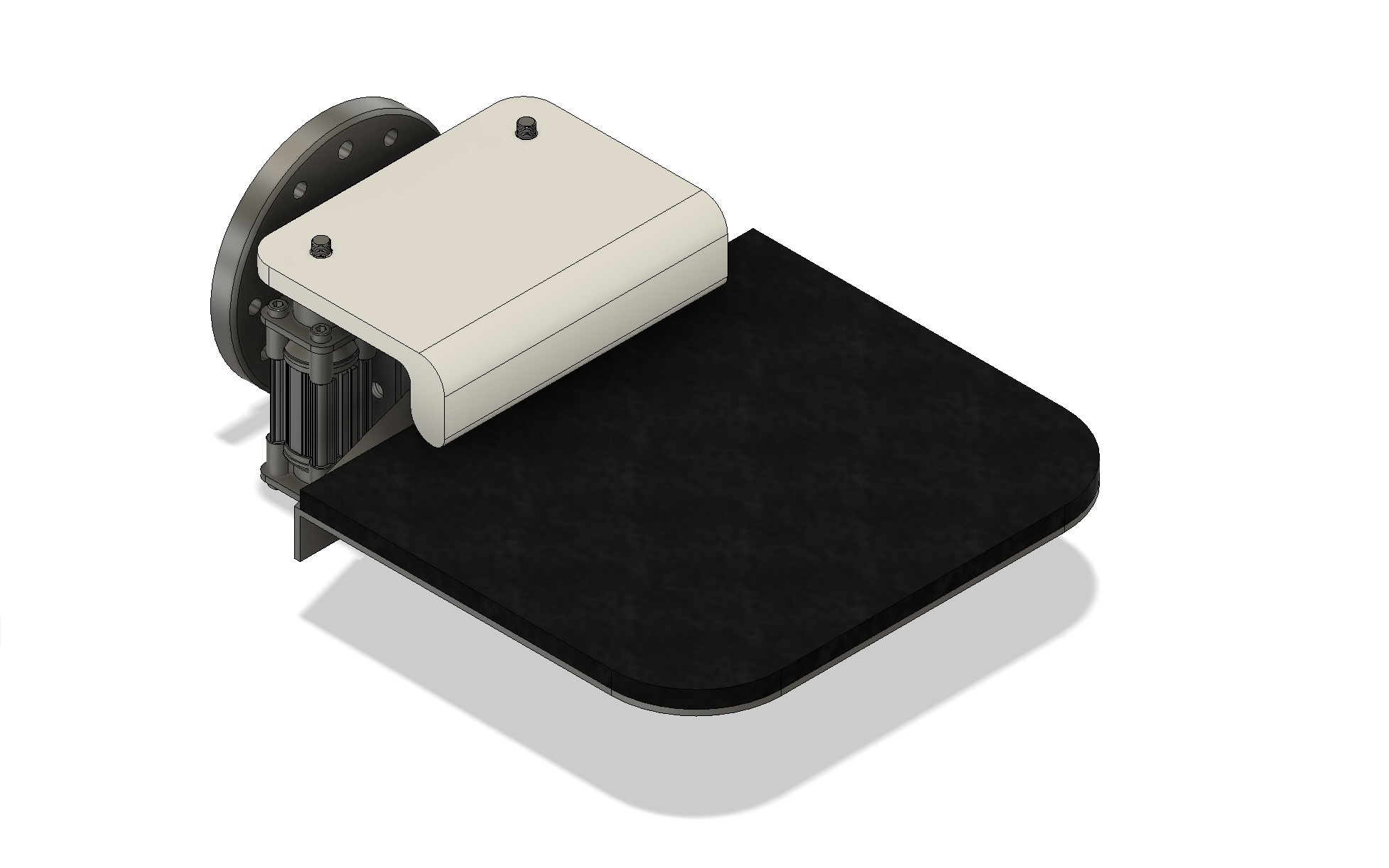

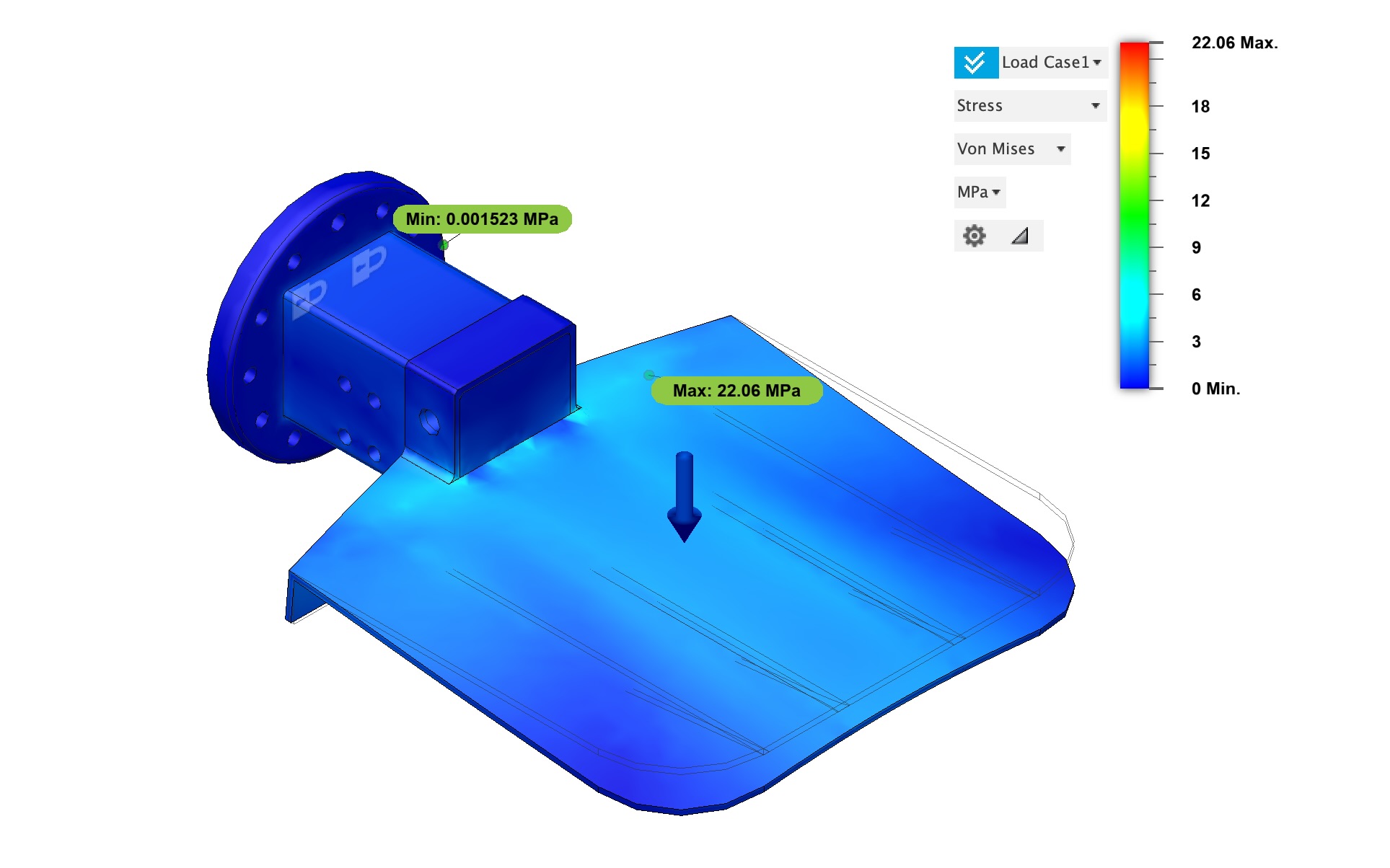

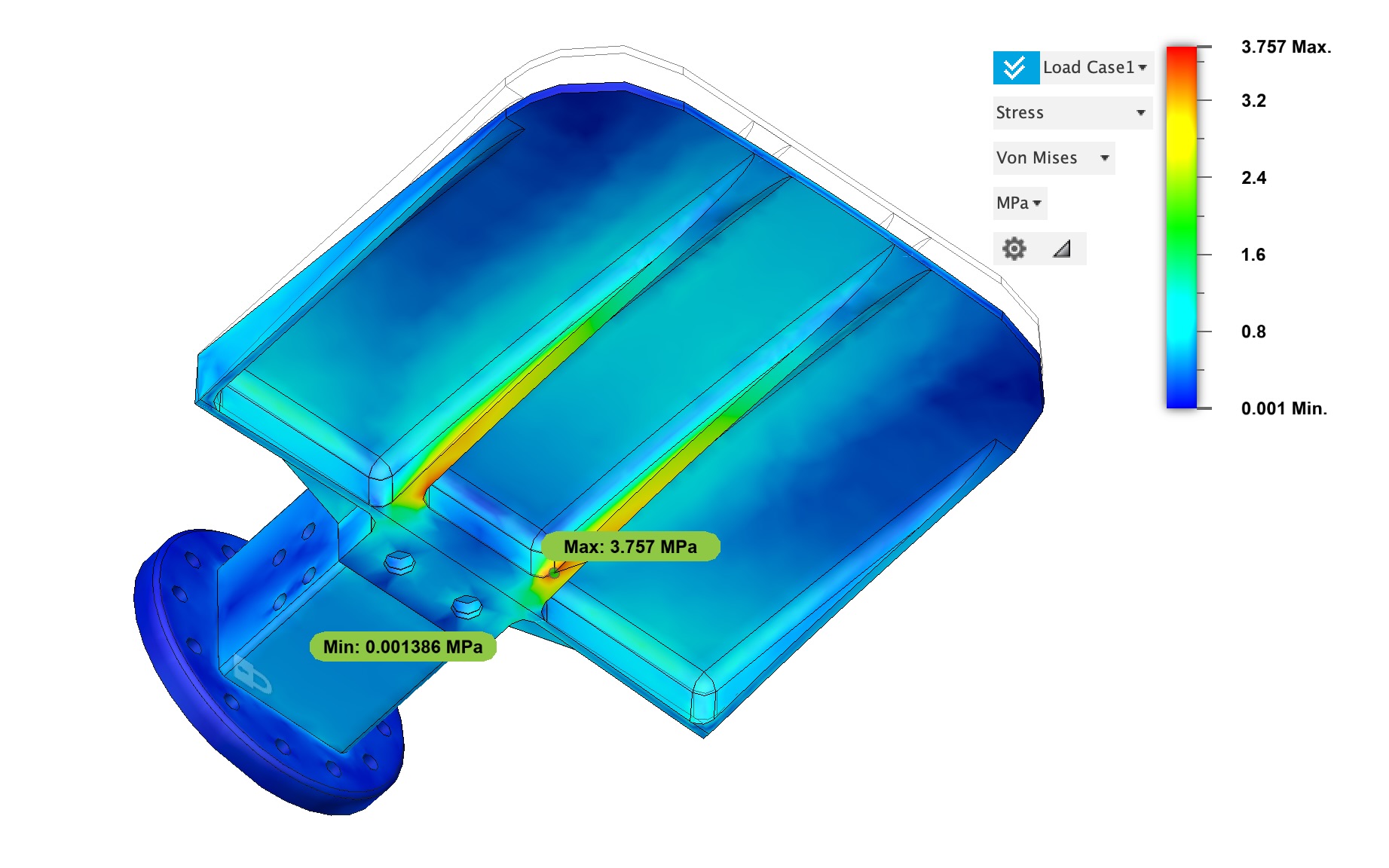

The project initiated with the conceptualization and design of a bio-inspired two-finger gripper tailored for industrial cake production and furnace loading applications. Utilizing Autodesk Fusion 360, the design was developed and later optimized using Kompas 3D (Russian CAD Software) to ensure it was both lightweight and functional. Finite Element Method (FEM) analyses were conducted to assess and ensure the structural integrity of the gripper under operational conditions.

To simulate real-world industrial scenarios, the assembly line processes were modeled using ABB Robot Studio, which allowed for precise planning and execution of robotic tasks. This integration aimed to enhance the functionality and efficiency of the assembly lines, specifically tailored to meet the demands of the cake industry.